Sunlite Science & Technology, Inc., a pioneer in LED technology (est.1996), started UV LED manufacturing in 2006. Sunlite UV LEDs are now used for flexo printing, screen printing, screen exposure and adhesive curing. Sunlite once manufactured its own LED wafers and chips, giving us the technical expertise to customize LED product to offer its best potential for a targeted application. Sunlite UV LED units produce more usable UV energy, deliver exceptional curing, and have longer curing unit lifetimes than competitors’ units.

UV LED v.s. Traditional UV

- UV LED has higher energy efficiency, longer lifetime, lower operating temperature than conventional UV lamps, and is environmental friendly.

- UV LED curing unit eliminates the need for large exhaust fans to remove ozone, freeing up space and saving money on equipment and electricity costs.

- UV LED curing unit does not have a warm up or cool down time. Frequent on and off cycling will not affect the lifetime of a UV LED curing unit.

- UV LED curing units do not generate ozone, do not contain mercury, and emit only UV-A wavelength light close to the visible spectrum

Sunlite – Pioneering UV LED Curing!

- Save additional ~10% energy

- Uses room temperature cooling to eliminate condensation

- All curing units are Scalable from 4” to over 100”

- UV LED modules are highly efficient and can be individually replaced on site

SUNLITE PATENTED AS-LED TECHNOLOGY

— HEAT DISSIPATION

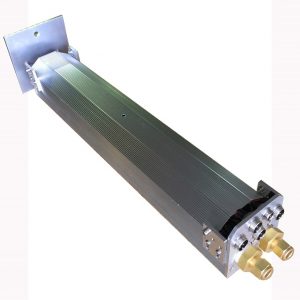

Sunlite Application Specific LED (AS-LED) Modules have chips directly mounted on silver plated copper to ensure the smallest number of insulating layers between the UV LED chips and the cooling water. This minimized temperature difference between LED chips and cooling water allows for room temperature cooling for the LED curing head.

— OPTICS

Sunlite uses single, domed glass lens with no airgap to LED chips to maximize the amount of UV energy directed towards the curing surface. This lens design typically increases the energy output by 44%, comparing to flat lens.

SUNLITE PATENT PENDING SYSTEM

— Sunlite’s simple and compact system design involves fewer components and less material and has better performance than other UV curing systems.

— Includes overheat protection design

— Large cooling capacity, no clogging

— Water lines can be connected either at front or back

— Water channels of the LED curing heads can be linked either in series or in parallel

— Scalable from a curing length of 4 inches to 100+ inches. Customized designs are available upon request!

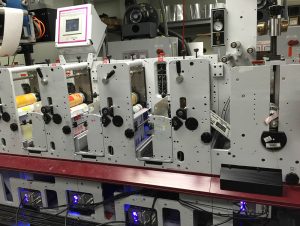

Sunlite’s UV LED Curing for Flexo Printing

Sunlite’s UV LED Curing for Flexo Printing

Flexo printing (also known as flexography) is a type of printing process that uses rollers and a flexible relief printing plate. Flexo printing technology can be used for printing on a wide variety of substrates including plastics, metallic films, cellophane, and paper. Flexo printing is the ideal process for printing packaging materials such as corrugated containers, paper sacks, plastic bags, food wrappers, and envelopes.

Sunlite’s Water-cooled UV LED Curing Unit is ideal for use with flexo printing at speeds of over 400 ft/min. The width of the curing area can be standard 10”, 13” or 17” or other custom width. The equivalent intensity is up to 26W/cm2. Sunlite’s water-cooled curing unit generates far less heat than traditional mercury UV lamps, which allows the stations of the flexo press to cure shrink sleeve (shrink film) without the need for roller chillers to prevent melting of the film.

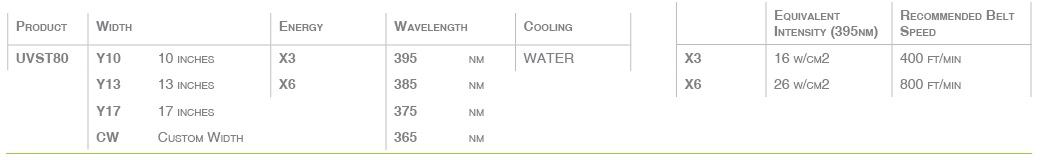

Sunlite’s UVST80 Series

UVST80 LED Curing Unit Product Specs

Features of Sunlite’s UVST80 LED Curing Unit used for Flexo Printing

- Water-cooled system

- Operating lifetime of 20,000+ hours

- Product curing length of 10, 13, or 17 inches

- Instantaneous on/off and dimming capabilities

- Equivalent power intensity as high as 26 Watts/cm2

- Automatic turn on/turn off feature to match printing process

- Environmentally friendly (no mercury contained in LED lights)

- Does not produce ozone (or require exhaust fans for ozone removal)

- LEDs can be placed very close to the substrate (0.25 inches is recommended for most applications)

Sunlite’s UV LED Curing for Screen Printing

Screen printing (also called silk screening) involves a screen (the image carrier) and a porous mesh stretched tightly over a frame. Proper tension of the mesh is essential to ensure good registration of the ink, which is transferred to the substrate using a squeegee. The belt speed used for a screen printing press is significantly slower than that of a flexo printing press. However, screen printing presses have the advantage that they can be used to create very wide prints (such as banners), while flexo printing presses can print only much narrower documents (up to ~17 inches wide at most).

Both water-cooled UV LED curing heads (UVST80) and the air-cooled UV LED curing heads (UVST85) are scalable and are therefore both recommended for screen printing to cure prints from 4 inches to over 100 inches.

Sunlite’s UVST80 Series

UVST80 LED Curing Unit Product Specs

Features of Sunlite’s UVST80 LED Curing Unit

- Water-cooled system

- Operating lifetime of 20,000+ hours

- Fixture length is scalable from 4 to 102 inches (or more)

- Instantaneous on/off and dimming capabilities

- Equivalent power intensity as high as 26 Watts/cm2

- Automatic turn on/turn off feature to match printing process

- Environmentally friendly (no mercury contained in LED lights)

- Does not produce ozone (or require exhaust fans for ozone removal)

- LEDs can be placed very close to the substrate (0.25 inches is recommended for most applications)

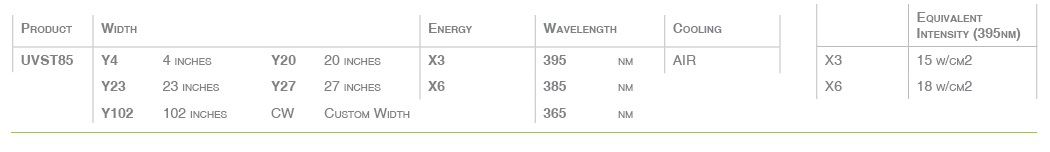

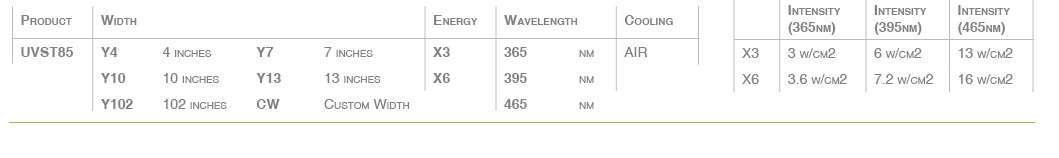

Sunlite’s UVST85 Series

UVST85 LED Curing Unit Product Specs

Features of Sunlite’s UVST85 LED Curing Units

- Air-cooled system

- Operating lifetime of 20,000+ hours

- Instantaneous on/off and dimming capabilities

- Environmentally friendly (does not contain mercury)

- Fixture length is scalable from 4 to 102 inches (or more)

- Does not produce ozone (or require an exhaust fan to remove ozone)

- Can be automatically controlled to turn on only when the printing unit is in operation

Sunlite’s UV LED Curing Products for Digital Printing

Sunlite recommends using its air-cooled UV LED curing units for digital printing. Sunlite’s air- cooled UV LED curing units can cure prints with widths ranging from 4 to over 100 inches. The equivalent intensity is up to 18W/cm2.

Sunlite’s UVST85 Series

UVST85 LED Curing Unit Product Specs

Features of Sunlite’s UVST85 LED Curing Units

- Air-cooled system

- Operating lifetime of 20,000+ hours

- Instantaneous on/off and dimming capabilities

- Environmentally friendly (does not contain mercury)

- Fixture length is scalable from 4 to 102 inches (or more)

- Does not produce ozone (or require an exhaust fan to remove ozone)

- Can be automatically controlled to turn on only when the printing unit is in operation

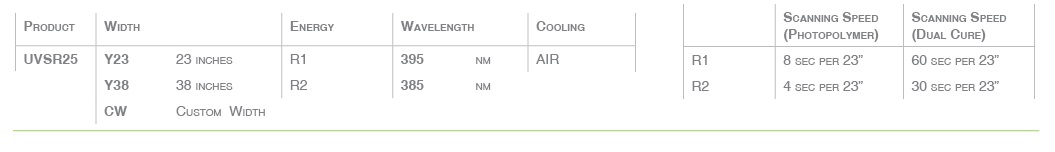

Sunlite’s UV LED Screen Exposure Scanning Bar

Screen Exposure Units are used for many conventional exposure applications, such as those used to make screens used for printing. Most screen exposure units involve (1) placing an object to be cured inside of the unit, (2) turning the unit on, and (3) waiting the length of time required for the object to be fully cured.

In 2014, Sunlite made the first UV LED Screen Exposure Scanning Bar (shown below) using an array of SR25 modules that emit high-intensity UV light. The scanning bar is attached to a mechanical arm that can move the bar over a given surface at a desired speed. The UV light emitted by the SR25 modules cures objects that it comes into contact with as the bar moves over the surface.

Sunlite’s UVSR25 Series

Sunlite’s UV LED Screen Exposure Scanning Bar has two major benefits:

- The high-intensity UV light emitted provides a faster curing time than traditional low-power LED screen exposure units (which require a curing time of approximately one minute for many applications).

- It is simple in design.

Features of Sunlite’s SR25 Screen Exposure Scanning Bar

- Air-cooled system

- Life span of 20,000+ hours

- Environmentally friendly (no mercury)

- Instantaneous on/off and dimming capabilities

- Fixture length is scalable from 4 to 100 inches (or more)

- Can be used as “stand alone” or combined with an inkjet system

- Can be automatically controlled to turn on with a control signal

![]()

Sunlite UV LED Adhesive Curing Unit

UV cure adhesive products are used in the production of circuit board, glassware, glass furniture, acrylic glass, for the optical industry and medical field.

Sunlite’s UVST85 Series

Features of Sunlite’s UVST85 LED Curing Units

- Air-cooled system

- Operating lifetime of 20,000+ hours

- Instantaneous on/off and dimming capabilities

- Environmentally friendly (does not contain mercury)

- Fixture length is scalable from 5 to 102 inches (or more)

- Does not produce ozone (or require an exhaust fan to remove ozone)

- Can be automatically controlled to turn on only when the printing unit is in operation

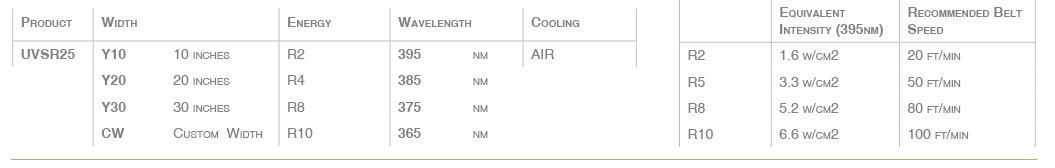

UVSR25 Series

UVSR25 LED Curing Unit Product Specs

Features of Sunlite’s UVSR25 LED Curing Units

- Air-cooled System

- Life Span of over 20,000 hours

- Instantaneous on/off and dimming capabilities

- Equivalent power intensity up to 6.6 Watts/cm2

- Environmentally friendly (do not contain mercury)

- Fixture length is scalable from 5 to 102 inches (or more)

- Do not produce ozone (or require an exhaust fan to remove ozone)

- Can be automatically controlled to turn on only when the printing unit is in operation

Customized Designs!

Call us at (785) 856-0219 for more details and to custom design your UV LED curing unit.