Sunlite’s UV LED Screen Exposure Scanning Bar

Screen Exposure Units are used for many conventional exposure applications, such as those used to make screens used for printing. Most screen exposure units involve (1) placing an object to be cured inside of the unit, (2) turning the unit on, and (3) waiting the length of time required for the object to be fully cured.

In 2014, Sunlite made the first UV LED Screen Exposure Scanning Bar (shown below) using an array of SR25 modules that emit high-intensity UV light. The scanning bar is attached to a mechanical arm that can move the bar over a given surface at a desired speed. The UV light emitted by the SR25 modules cures objects that it comes into contact with as the bar moves over the surface.

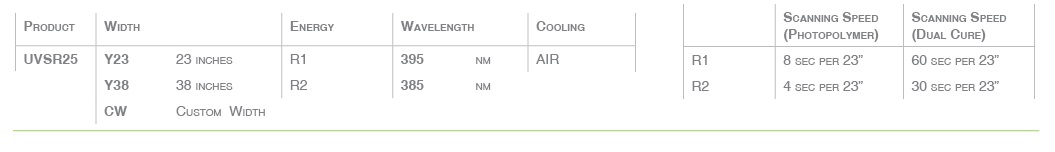

Sunlite’s UVSR25 Series

Sunlite’s UV LED Screen Exposure Scanning Bar has two major benefits:

- The high-intensity UV light emitted provides a faster curing time than traditional low-power LED screen exposure units (which require a curing time of approximately one minute for many applications).

- It is simple in design.

Features of Sunlite’s SR25 Screen Exposure Scanning Bar

- Air-cooled

- Life span of 20,000+ hours

- Environmentally friendly (no mercury)

- Instantaneous on/off and dimming capabilities

- Fixture length is scalable from 4 to 100 inches (or more)

- Can be used as “stand alone” or combined with an inkjet system

- Can be automatically controlled to turn on with a control signal

- Energy efficient (80% less power consumption compared with traditional fixtures)

Customized Designs!

Contact us at (785) 856-0219 for more details and to custom design your UV LED Scanning Bar.